3D Printing and Materials Science Consulting

What we do

3Degrees is an independent, technology-agnostic 3D Printing and Materials Science consulting company. We are uniquely able to understand our client’s problems and help them implement winning 3D Printing Solutions through practical insights and materials expertise. No matter where you are in the adoption process we can help take your organization to the next level.

Core Capabilities

We work with diverse companies around the world to enable them to stay ahead of the curve.

Develop and Test Materials

We have a deep expertise in Materials Science and have worked with chemical and materials companies interested in entering the 3D Printing supply chain

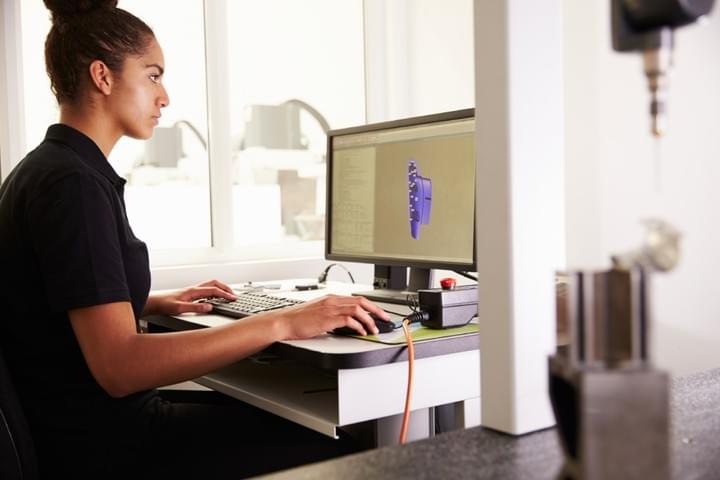

Establish Production Capabilities

Help product-focused companies identify, build and expand their use of 3D Printing in targeted applications and business scenarios such as aerospace, automotive, consumer products and medicine

Build Your Workforce

We train designers, engineers and business leaders at both an introductory and advanced level on this powerful technology

Manage Your 3D Printing Data

Our customized software tool, traceAM, makes it easy to streamline your project management and documentation processes at all stages of the 3D Printing workflow, including traceability and quality management within your organization and throughout your supplier base.

How we work

We help you rethink your manufacturing approach to de-risk your supply chain and increase flexibilityIDENTIFYWe bring deep technical expertise and market intelligence to design a strategic, actionable strategyINFORMWe educate stakeholders and team members about best practices, safety and industry standards to ensure adoption and long-term successIMPLEMENTOur experts will work side-by-side with you to test novel applications, try or develop new materials and evolve your strategy to maximize your ROI

Client Case #1

Creating a 3D Printing Strategy for Production

After over a decade of using 3D Printing for prototyping, an industrial and construction components company was stuck trying to find a viable approach to use 3D Printing for production.

We conducted our proprietary "Production 3D Printing Readiness Evaluation" that examined their overall AM Strategy, People/Organization Structure, Processes, Materials, Software and Facilities. Our analysis helped them develop a clear roadmap for building out their production capabilities.

Client Case #2

Developing New Materials

A top 10 global materials manufacturer wanted to enter the 3D Printing market and needed help evaluating opportunities and performing validation testing.

We helped them get up to speed quickly and served as a technical resource for market strategy and testing as they built up their materials portfolio. They are now actively selling 3D Printing materials commercially.

Client Case #3

Setting up a Production Facility

One of the world's top consumer product brands had just invested over half a million dollars in 3D Printing equipment and was looking to operationalize the facility as quickly as possible.

We provided best practice advice and guidance on material and process validation, operating procedures and quality management, which enabled them to launch their first commercial 3D Printed product in a matter of months.

Client Case #4

Workforce Development

A global leader in product, materials and workplace safety was looking to support its manufacturing partners by developing a workforce training curriculum on Additive Manufacturing.

We provided subject matter expertise and aided in the development and deployment of an international training curriculum, which now has been taught to dozens of leading manufacturing companies.

Client Case #5

Reducing Spare Parts Inventory

A company focused on making low-volume stamped parts was looking to digitize its tooling and mold inventory.

We evaluated the organization's inventory of spare parts and used our proprietary approach for 3D Printing selection to identify high-quality candidates for 3D Printing replacement. We worked with them to set-up a workflow to ensure that the critical variables and instructions were digitally documented.

3Degrees Discussions

A weekly podcast dedicated to the leaders, innovators, and entrepreneurs in the Additive Manufacturing industry. Through compelling interviews, Mike’s podcast highlights the advancements in the 3D Printing space along with providing the backgrounds of companies and the people who built them to where they are now. Mike has interviewed over 15 CEOs, over 11 Presidents of Additive Manufacturing and 3D Printing companies, and over 20 engineers all thriving in their professions. With over 59 hours worth of streamed content, each interview is impactful and enlightening. If this is your first time, tune into Mike's episode to learn more about him and the company.

Recent Interviews

DyeMansion, M. Holland, Boeing, Ford, NASA, MIT, REM Surface Engineering, Azul 3D, Alexander Daniels Global as well as many others.

3Degrees Discussions In-Depth

Want to know more about our guests and their careers in the additive and 3D Printing space?

For our 133rd episode, we had the pleasure of speaking with Janet Dickinson. Janet is the Cheif...For episode 132, we had the opportunity to sit down with Amy Alexander. Amy is a Unit Head of...We had the pleasure of speaking with David Scannapieco, the Scientific Development Management...More Posts

© 2023 3Degrees, LLC